What is a real marine battery ?

Don’t Buy Any Lithium BatteryUntil You’ve Read This

Why Choose Us

There Are So Many LiFePO4 Batteries on the Market, But...

There are numerous household LiFePO4 batteries on the market, starting at around $150-$200 per 100 amp-hours. However, not every such battery is suitable for installation on a boat. Often, these batteries won't last long on a boat and can pose a fire risk.

How Long Does a Lithium Battery Last Before It Degrades?

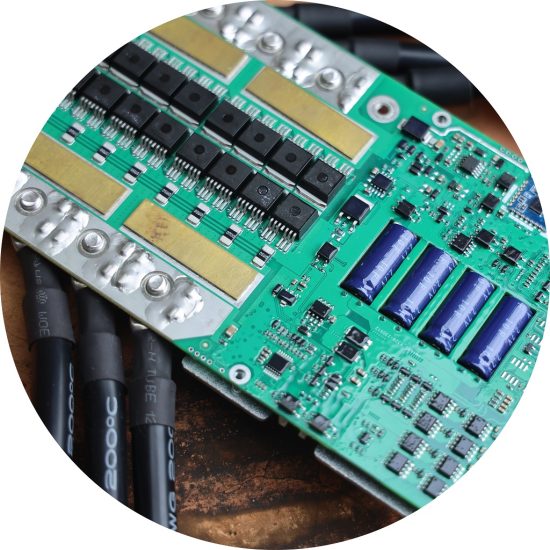

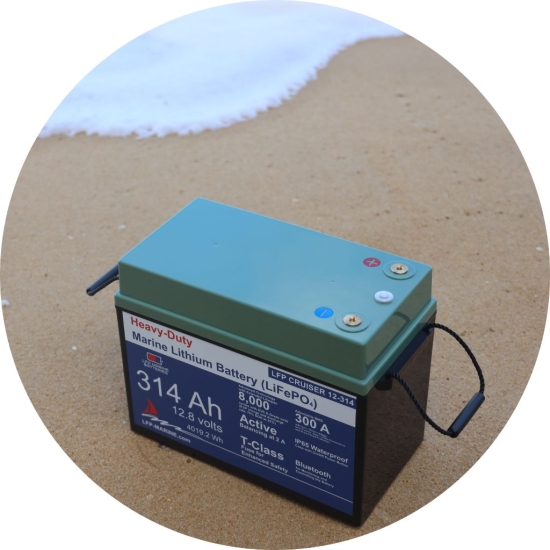

First of all, it depends on the generation of cells and their design chemistry. Normally, a manufacturer specifies this in the documentation. In the "Cruiser" battery series, we use the latest generation of lithium-iron-phosphate (LiFePO4) EVE A-Grade cells with 8,000 cycles before degradation. But this is only a physical test of the cell, under ideal laboratory conditions, and many parameters reduce this number during real operation as part of an assembled battery. The tests are carried out at a temperature of 25 degrees Celsius, and increasing the temperature dramatically reduces the number of cycles. For example, an average cell on the market (designed for 6000 cycles at a temperature of 25 degrees) will show a result of only 2500-3000 cycles at a temperature of 45 degrees Celsius. Many users operate batteries in the tropics and subtropics, where ambient temperatures are 30+°C. A marine battery typically has a sealed, moisture-proof enclosure with a waterproof rating of at least IP65. As a result, the temperature inside the battery case is always significantly higher than the ambient environment. Voltage drop in the wires generates heat. The only way to minimize this temperature increase is to reduce the internal resistance of all battery components, such as the BMS and wires. That's why we use internal wires with a cross-section of at least 64-75 mm² and a 300-amp BMS with low internal resistance. However, thick copper wires and powerful BMS systems are expensive, so most manufacturers use the minimum cross-section and smaller BMS without considering voltage drop and the generation of additional heat. Wire thickness and internal resistance matter for Marine Grade batteries! During manufacturer tests, prismatic cells are compressed. If compression is not used, the number of cycles decreases, sometimes by 20-30%. Compression is especially important at high currents close to 0.5C and above. We often see such currents in marine applications because we typically use 12-volt systems and are limited by space for battery installation: small total capacity and high current mean a high C-rate. In the Cruiser battery series, the cells are compressed and fixed in the module. However, most manufacturers skip compression to save costs. Compression matters for marine applications!

Cell balancing is important!

Each cell changes its internal resistance over time. All cells are connected in series inside the battery, and different internal resistances result in voltage differences. The voltage difference can lead to the battery stopping operation or, without protection, to battery failure and fire. Cell balancing is critical. There are two methods of internal balancing. The first one is passive balancing. It is not suitable for marine batteries. The voltage difference is equalized by dissipating energy as heat. This is not effective and causes an increase in temperature inside the case, which reduces the number of battery cycles, as discussed above. In addition, the capabilities of passive balancers are currently limited to 50-400 mA. Most often, more is needed.

The second way is active balancing. It’s integrated into our batteries. It is much more efficient, with a balancing current of up to 2 amps (Cruiser series), voltage distribution between cells, and no extra heat generation. Often, manufacturers save costs on balancing features or equip batteries with only passive balancing. This is unacceptable for marine batteries.

Safety Is Extremely Important When You're at Sea.

Any marine battery must have the following protections:

1. Over and Under-voltage Protection (Against Overcharge and Overdischarge, Performed by BMS).

Due to an imbalance or improper charger adjustment, the cells may be damaged and cause a fire. If the voltage exceeds the permitted limits, the BMS physically disconnects the battery. This function is usually present in all batteries, even the cheapest ones with a BMS.

2. Overcurrent Protection (Performed by BMS and Fuse)

If the load does not match the battery's C-rate, this can lead to overheating of the wires and a fire. Unfortunately, this function is either absent or not adjustable in cheap batteries. In our batteries, the BMS allows us to set the maximum permitted current precisely.

3. Over and Under-temperature Protection (Performed by BMS with Temperature Sensors)

Temperature sensors measure the actual temperature of the cells inside the battery. Cells must not be charged at temperatures below 5°C and operate at above 55-60°C. Cheap batteries lack this function and often operate at very high temperatures, leading to degradation. In our batteries, the temperature sensors are connected to the BMS, which monitors the temperature.

4. Short-Circuit Protection (Performed by a BMS and Fast Active Fuse)

In the event of an accident or a short circuit on the DC bus, the battery must be disconnected; otherwise, wires and components will be damaged, potentially causing a fire.

Cheap batteries may lack this protection entirely! In most batteries, protection is handled by the BMS itself. If the current is very high or the BMS is phusically damaged, the short circuit protection functionality will not be available. Unfortunately, "household" batteries lack 100 % internal short-circuit protection (such as a fuse or circuit breaker).

We aim to provide the highest level of protection. The lives of the crew, the safety of the boat, and maintaining electrical service at sea are our priorities. That's why our "Cruiser" series batteries are equipped with a fast current-limiting Class-T fuse with an interrupt rating of 20,000 amps, as well as arc protection. In most cases, this not only prevents fires but also saves your battery and allows quick restoration of service at sea.

We often hear that all LiFePO4 batteries are the same—you can buy the cheapest one and install it on your boat. Unfortunately, many people can't imagine the possible negative scenarios directly related to the battery's characteristics. A bad battery is like a bad car without an engine temperature sensor, seat belts, speedometer, tachometer, airbags, or proper brakes. It might seem okay to drive, but would you put your family in it?

Key Features

of the CRUISER Marine Battery

Smart Technology Integration

The CRUISER battery is fully adjustable via Bluetooth, allowing users to monitor and manage battery performance using a smartphone. Additionally, data can be output to a remote personal touchscreen display, providing real-time information at your fingertips.

Advanced Battery Management System

Equipped with a powerful 300 amps BMS, the CRUISER battery includes the most modern active cell balancing function, with a balancing current of up to 2 amperes. This system ensures optimal performance and longevity of the battery cells.

Superior Safety Features

Safety is a top priority for the CRUISER series. Each battery is equipped with the fast current-limiting, short-circuit, and arc-preventing T-Class fuse. Additionally, it includes temperature sensors, high and low-temperature protection, over and under-voltage; overcurrent ensuring maximum safety in all conditions.

Conclusion

The CRUISER Marine Battery Series

In summary, the "Cruiser" marine battery series sets a new standard in the industry of "Drop-in" marine batteries with its smart technology, powerful performance, superior safety features, and compact design. Whether you are replacing lead-acid batteries or looking for a high-performance solution for your boat, the "Cruiser" battery series is the ultimate choice.

Cart is empty

Cart is empty